ETO STERILIZER

The Ethylene Oxide (ETO) Sterilizer is an essential device in the medical, pharmaceutical, and laboratory fields, designed specifically to sterilize items that are sensitive to heat or moisture. Ethylene Oxide gas is a potent sterilizing agent, capable of eliminating a wide range of microorganisms, including bacteria, viruses, and fungi, making it ideal for complex and delicate instruments.

ETO sterilization is conducted at low temperatures, typically between 30°C to 60°C, which makes it suitable for materials that cannot withstand the high temperatures used in other sterilization methods. This includes a wide variety of materials such as plastics, optics, and electronics, which would otherwise be damaged by traditional sterilization techniques.

Neurosurgeons – Research Centers – Multispecialty Hospitals – Specialty Laboratories- Pharmaceuticals Applications- Specialty Hospitals- CATH Labs – Medical Institutes- Eye Specialists – Ortho Specialists – General Surgery Centers- Gynaec Care Units – Cardiothoracic Surgeons-Interventional Cardiologist – Plastic / Cosmetic Surgeons

Neurosurgeons – Research Centers – Multispecialty Hospitals – Specialty Laboratories- Pharmaceuticals Applications- Specialty Hospitals- CATH Labs – Medical Institutes- Eye Specialists – Ortho Specialists – General Surgery Centers- Gynaec Care Units – Cardiothoracic Surgeons-Interventional Cardiologist – Plastic / Cosmetic Surgeons

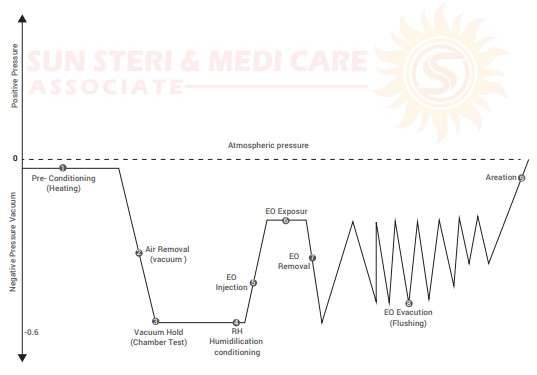

Ethylene Oxide Processing – Ethylene oxide (also known as EO or EtO) is a low temperature gaseous process widely used to sterilize a variety of healthcare products, such as single-use medical devices. Heat Sensitive Product would be doEtO Sterilization Process. Ethylene Oxide (EtO) gas is one of the most common ways to sterilize medical devices, a safe, tightly controlled, highly regulated process which is critical for preventing infections and ensuring patients have safe surgeries and medical treatments. ETO Sterilization is considered the sterilization method with the broadest application available for medical products and medical devices due to its effectiveness at lower temperatures and its general compatibility with a diversity of materials, resins, and product types, including: Polymer resin-based products.

Features

- Low-Temperature Operation: Designed to sterilize heat-sensitive materials, operating effectively at temperatures between 30°C and 60°C.

- Comprehensive Penetration: Ethylene Oxide gas permeates deep into items, including those with complex geometries, ensuring thorough sterilization.

- Advanced Control System: Equipped with precise controls for managing temperature, humidity, gas concentration, and exposure time, allowing for customizable sterilization cycles.

- Residual Gas Removal: Features an aeration system that efficiently removes residual Ethylene Oxide gas post-sterilization, ensuring items are safe to handle.

- Safety Features: Equipped with automatic pressure release valves, door interlocks, and real-time monitoring systems for enhanced operator safety.