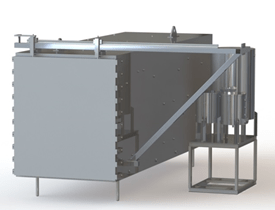

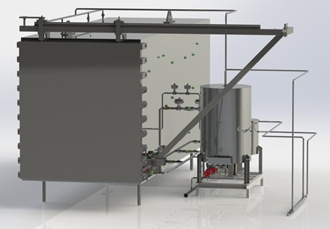

INDUSTRIAL BIG ETO / EO STERILIZER

An industrial big Ethylene Oxide (ETO) sterilizer is a large-scale device designed for the high-volume sterilization of medical equipment, pharmaceuticals, and other sensitive materials that cannot withstand high temperatures or moisture. These large ETO sterilizers are essential for facilities that require efficient, large-capacity sterilization solutions to meet high demand.

The sterilizer operates by introducing Ethylene Oxide gas into a sealed chamber where it is maintained at precise levels of concentration, temperature, and humidity. The process involves several critical stages: preconditioning to prepare the items and chamber environment, gas introduction to ensure thorough exposure, and aeration to remove residual gas and make the items safe for use.

These industrial models are built to handle substantial volumes of items, featuring robust construction and advanced control systems to manage and monitor the sterilization process. They are equipped with sophisticated safety mechanisms to handle the toxic and flammable nature of Ethylene Oxide, including leak detection systems, alarms, and automatic shut-off features to protect both operators and the environment.

These industrial models are built to handle substantial volumes of items, featuring robust construction and advanced control systems to manage and monitor the sterilization process. They are equipped with sophisticated safety mechanisms to handle the toxic and flammable nature of Ethylene Oxide, including leak detection systems, alarms, and automatic shut-off features to protect both operators and the environment.

Industrial Big ETO Sterilizer Turnkey project :- for ethylene oxide sterilization

We design, manufacture, control and qualify Ethylene Oxide Sterilizers (EO/ETO) for the sterilization of thermo sensitive products (sensitive to heat and humidity) like syringes, catheters, dialysis cartridges, plastic dressings, sutures, etc.

We are Ethylene oxide sterilizers manufacturer, the perfect method for medical device sterilization. Apart from designing and manufacturing the sterilizer, we also provide all the ancillary equipment in order to offer a complete sterilization unit by ethylene oxide process.

Ethyle Oxide Sterilization Chambers – EO machine :- Our design is modular type and gives the main advantage to divide the risk area in order to reduce the probability of having a potential explosive atmosphere. Those projects are customizable as we offer a very flexible design, according to the client requirements. Our chambers are prepared to work with All in One cycle. We also propose all the ancillary equipment for turnkey projects

Our standard design for Sterilizer machines goes from 1 CBM (Cubic Meter) up to 20 CBM (Cubic Meter) model, but are not limited and the dimensions and design can be adjusted according to the final user needs.

Our standard design for Sterilizer machines goes from 1 CBM (Cubic Meter) up to 20 CBM (Cubic Meter) model, but are not limited and the dimensions and design can be adjusted according to the final user needs.

Features

-

ETO /EO Sterilizer has been use for Sterile a Surgical Medical Device Products like I.V. Sets, Disposable Syringes, Disposable Surgical Set, catheter, Urine Bag, Packed Cotton Gauze, etc… to reduce microbiological load; and increase life span of material

- Modular construction of chamber

- Model is available from 1/2 CU.MTR TO 25 CU.MTR.

- Easy to operate.

- Fully automatic operation based on PLC control (optional).

- Semi-Automatic (Pneumatically Operated Ball Valve) Control.

- Contact parts are SS 304 / 316.

- Process time about 8-10 hrs.

- IQ/OQ/DQ documentation (OPTIONAL).

- EO Mixer Big Bottle / Cylinder use outside the Chamber under vacuum under special size. We can provide the Both Option Like Critrage Punchering System & Cylinder Mix EO system in the same EO Sterilizer under the limitation of Certain Sizes.

(Cubic Feet) | In CBM | Feet H X W X L | in Liters | Cylinder (20-80) | Cylinder (90-10) | |

|---|---|---|---|---|---|---|